-

Kitemark Certificate

-

DIN EN3 APPROVAL CERTIFICATE (SP 63/19)

-

DIN EN3 APPROVAL CERTIFICATE (SP 64/19)

-

DIN EN3 APPROVAL CERTIFICATE (SP 65/19)

-

TUV-ZERTIFIKAT Certificate (Z-IS-ESP1-MUC-18-09-790008-029-253)

-

TUV-ZERTIFIKAT Certificate (Z-IS-ESP1-MUC-18-07-790008-025-249)

-

TUV-ZERTIFIKAT Certificate (Z-IS-ESP1-MUC-18-07-790008-022-246)

-

TUV-ZERTIFIKAT Certificate (Z-IS-ESP1-MUC-18-07-790008-021-245)

-

TUV-ZERTIFIKAT Certificate (Z-IS-ESP1-MUC-18-04-790008-013-237)

-

TUV-Certificate of Conformity (Z-IS-ESA11-MUC-19-11-790008-032-291 Italy)

-

TUV-ZERTIFIKAT Certificate (Z-IS-ESP1-MUC-18-04-790008-014-238)

-

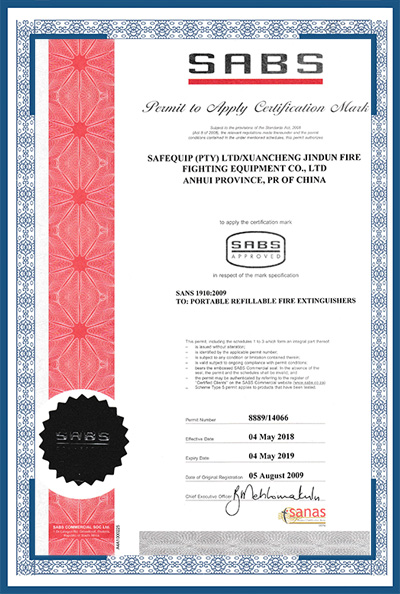

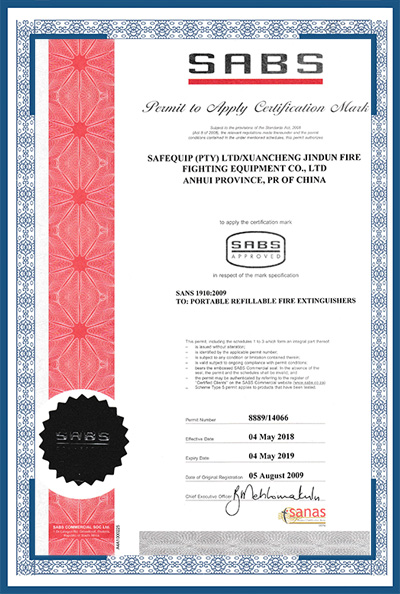

SABS (XCJD SANS 1910 8889-14066)

-

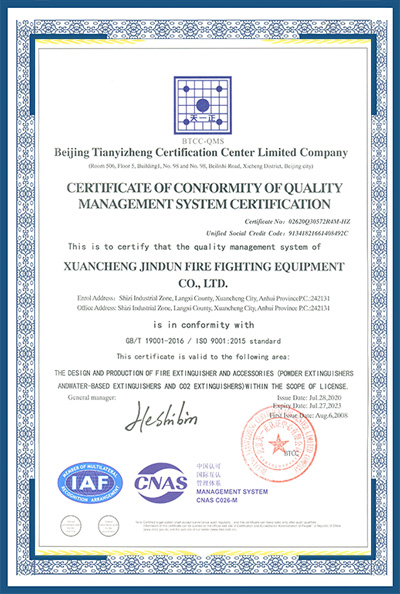

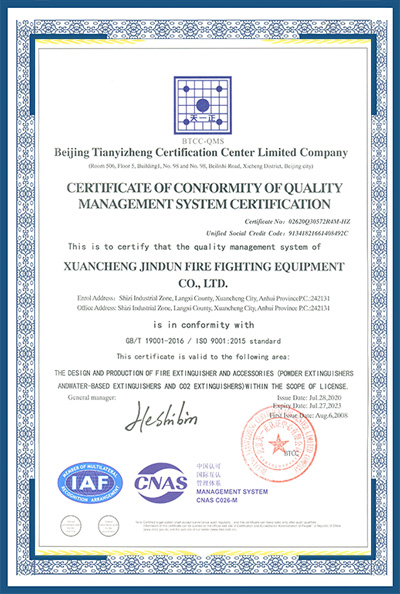

Certificate of conformity of quality management system certification

-

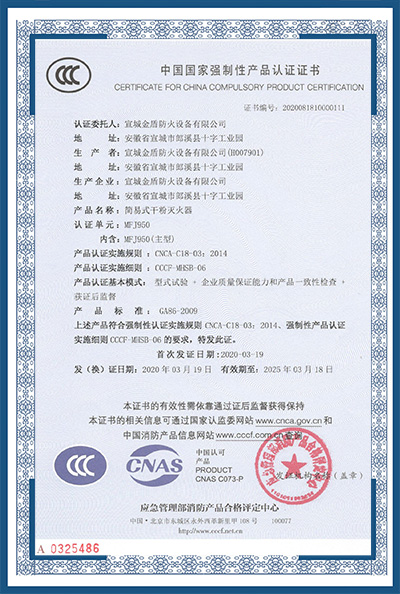

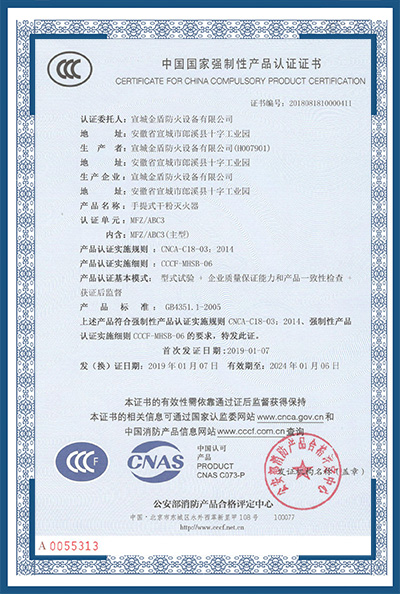

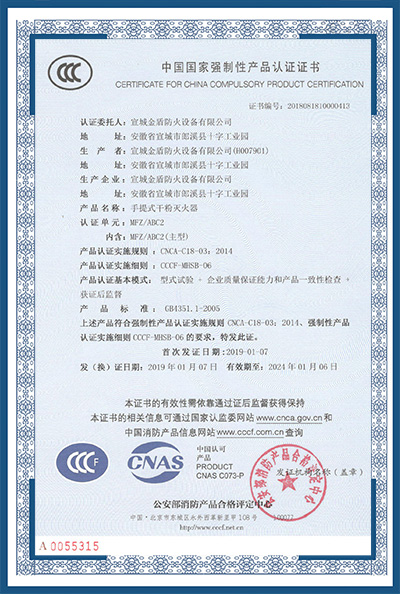

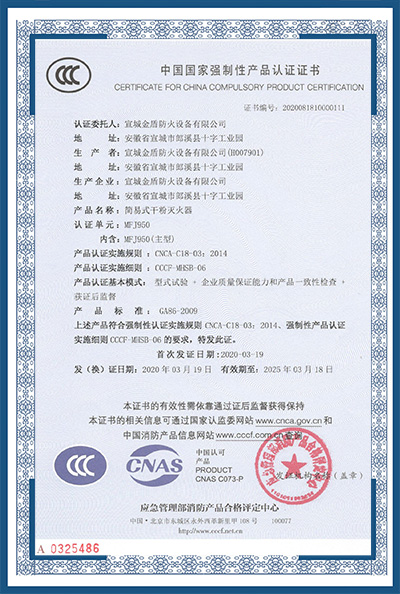

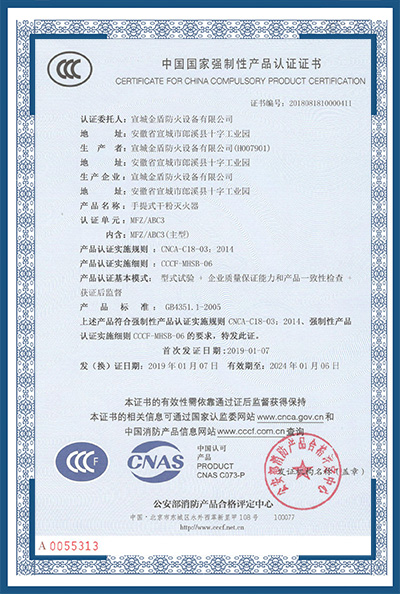

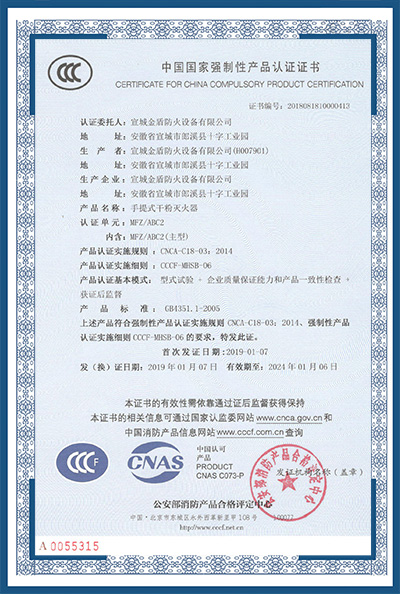

Certificate for China Compulsory Product Certification( portable dry powder extinguisher)

-

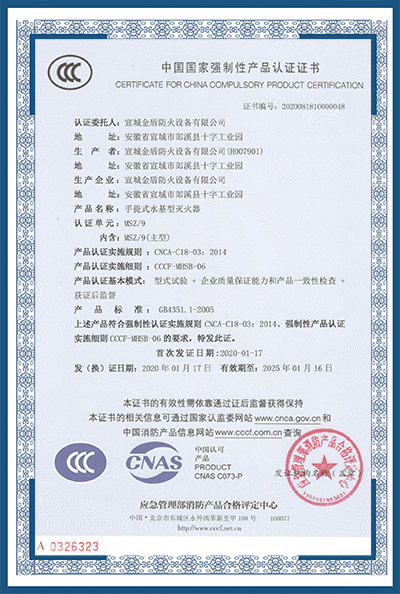

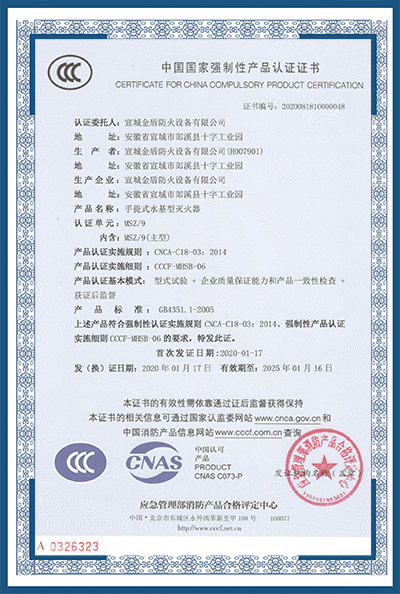

Certificate for China Compulsory Product Certification( 9L portable water-based extinguisher)

-

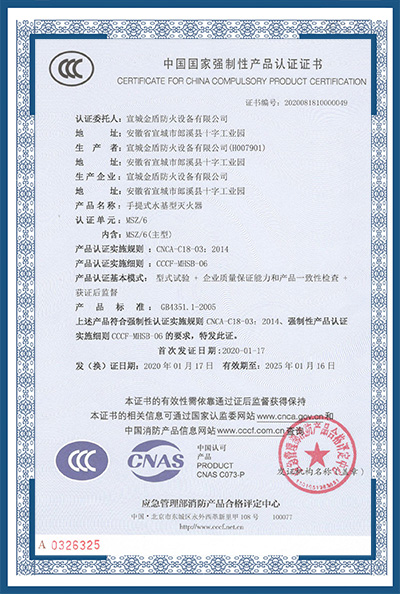

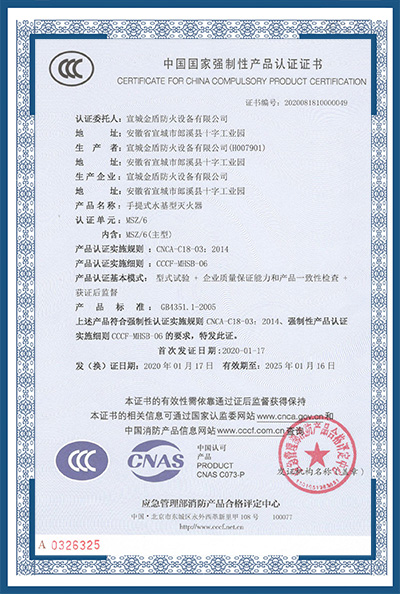

Certificate for China Compulsory Product Certification( 6L portable water-based extinguisher)

-

Certificate for China Compulsory Product Certification( 3L portable water-based extinguisher)

-

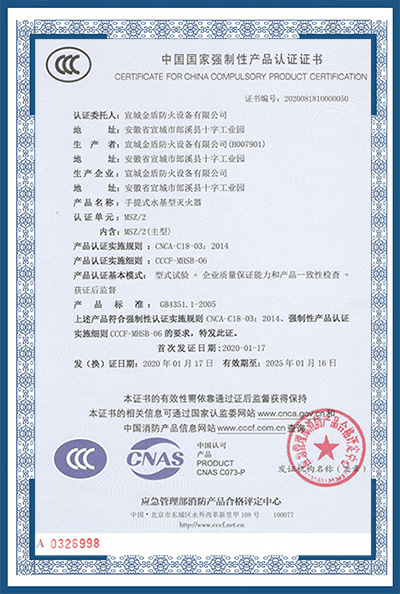

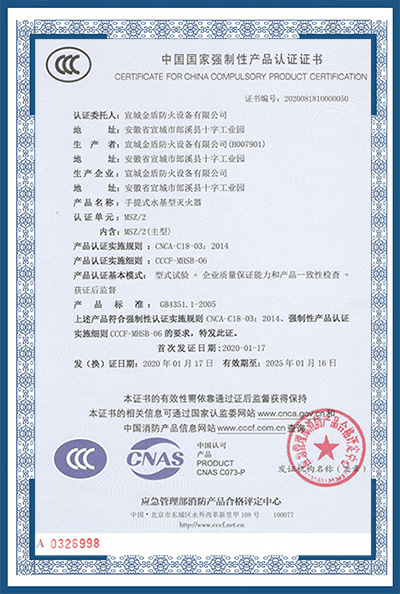

Certificate for China Compulsory Product Certification(2L portable water-based extinguisher)

-

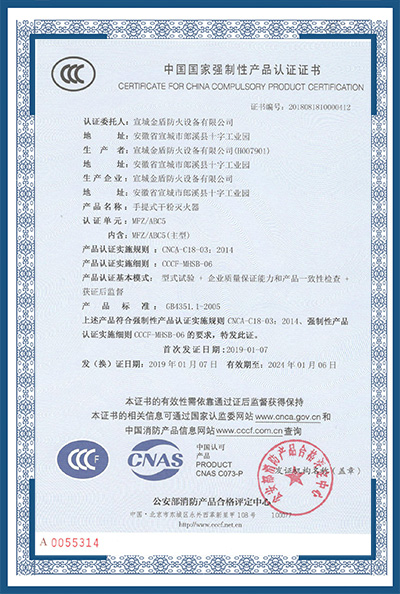

Certificate for China Compulsory Product Certification( 5KG dry powder extinguisher)

-

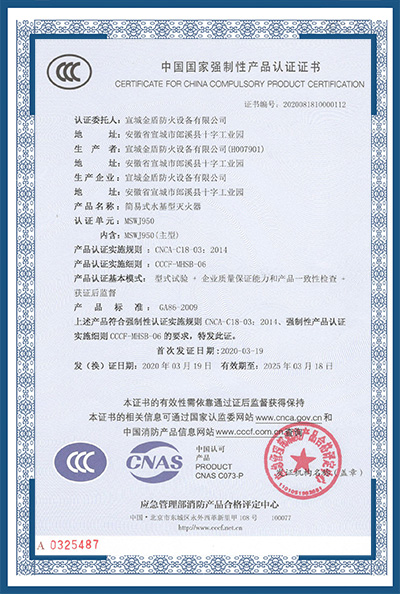

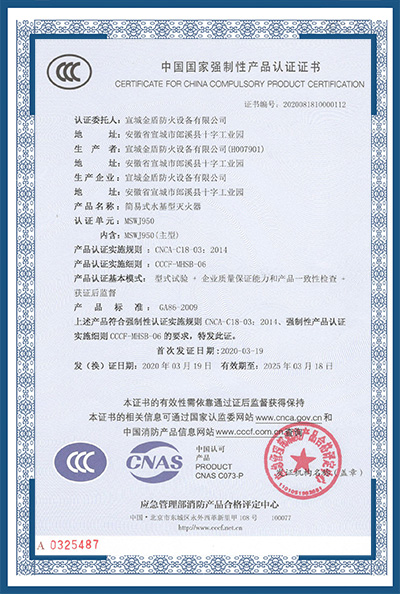

Certificate for China Compulsory Product Certification( portable water-based extinguisher)

-

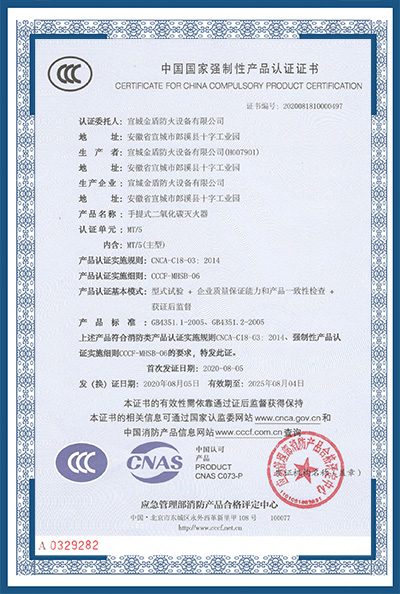

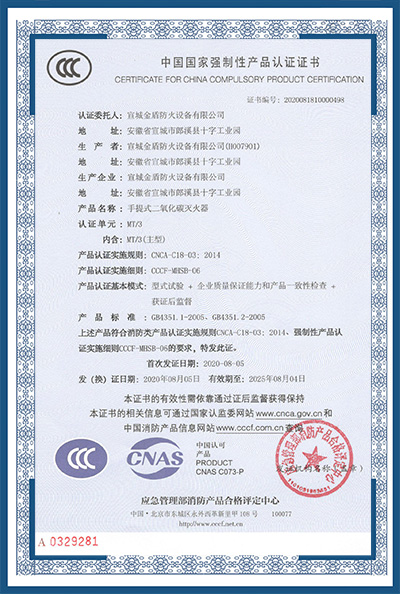

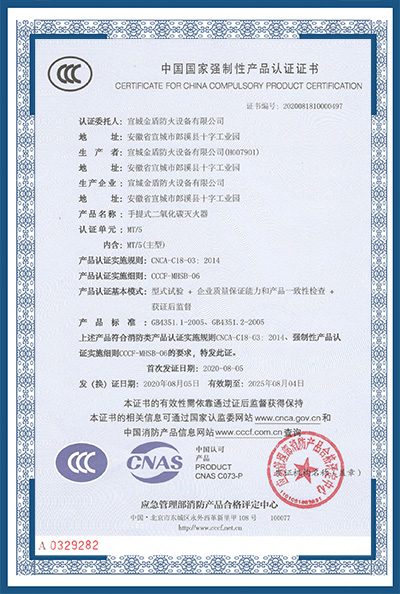

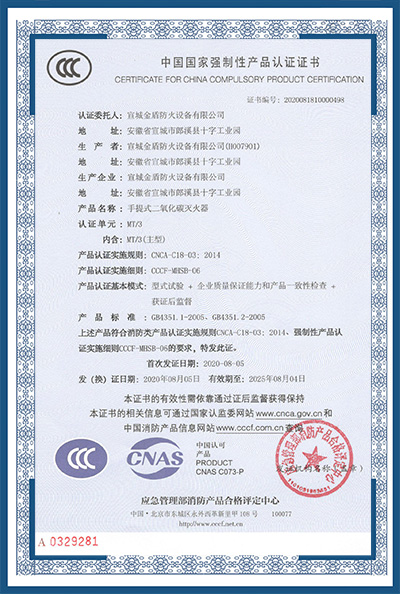

Certificate for China Compulsory Product Certification( 5KG CO2 extinguisher)

-

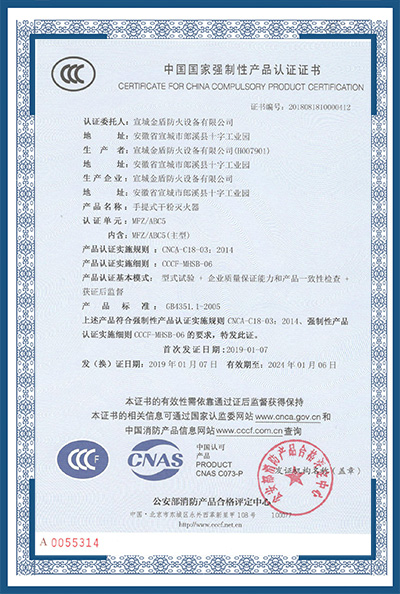

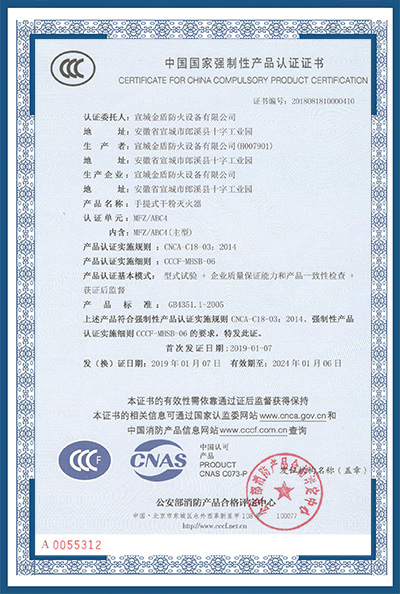

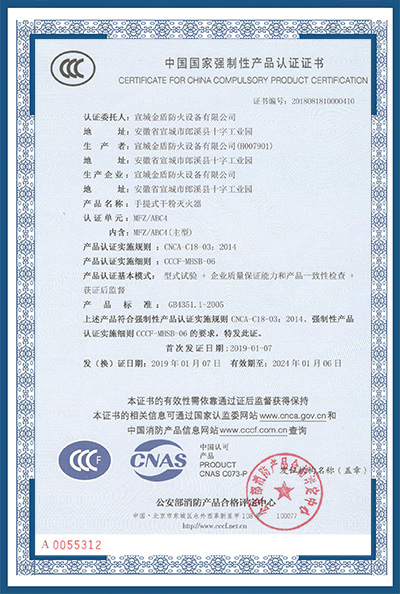

Certificate for China Compulsory Product Certification ( 4KG dry powder extinguisher)

-

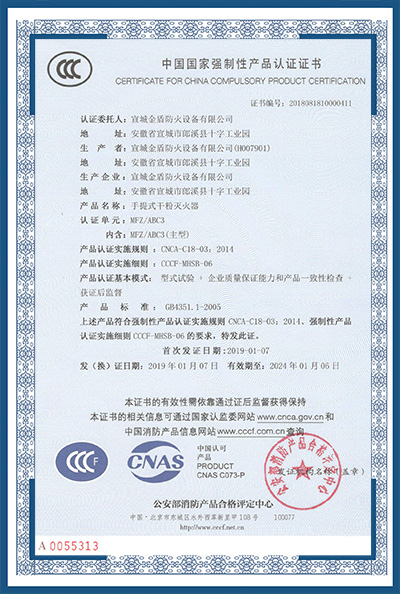

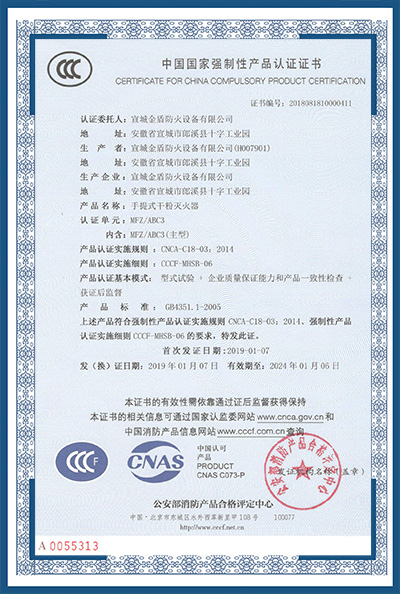

Certificate for China Compulsory Product Certification(3KG dry powder extinguisher)

-

Certificate for China Compulsory Product Certification(2KG dry powder fire extinguisher)

-

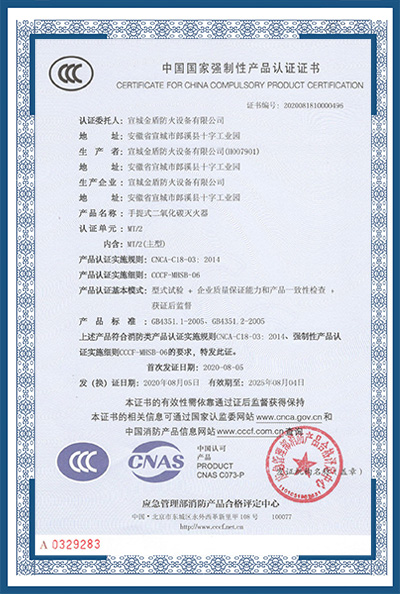

Certificate for China Compulsory Product Certification(3KG CO2 extinguisher)

-

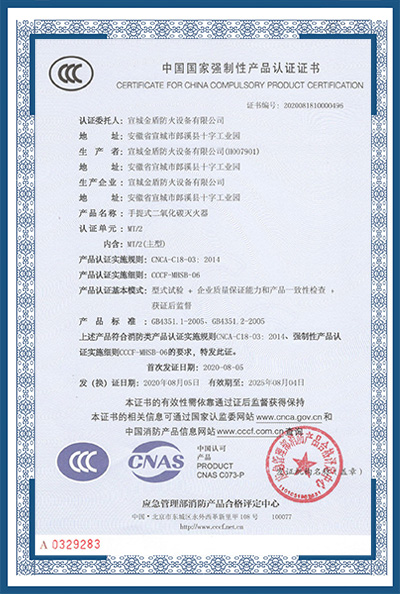

Certificate for China Compulsory Product Certification(2KG CO2 extinguisher)

-

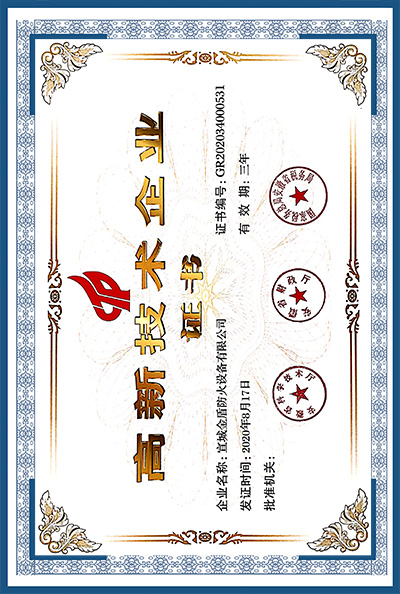

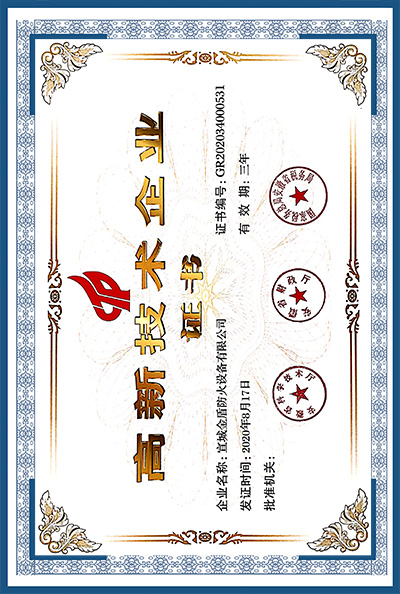

Certificate of High-tech Enterprise